Il existe des différences significatives dans la conception et l'utilisation entre 32 Écran tactile en pouces and PLC computers. Voici une comparaison détaillée entre les deux:

Diplôme Structure et Intégration

32 Écran tactile en pouces:

C'est un appareil qui intègre plusieurs fonctions comme un ordinateur, moniteur, et écran tactile.

It usually has a high degree of integration, integrating multiple functions into a compact body.

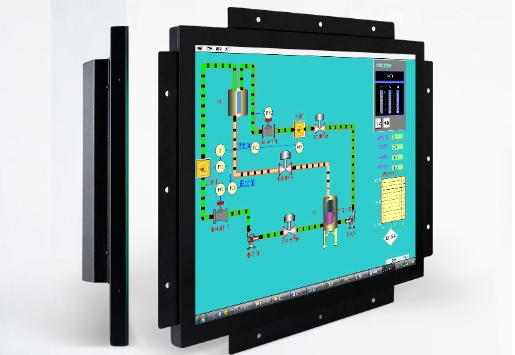

PLC computer (or PLC all-in-one machine):

It is a device that integrates PLC (Programmable Logic Controller) and touch screen together.

Its structure is relatively simplified, mainly including PLC controller, Écran tactile, necessary input and output interfaces, communication interfaces, etc..

Function and purpose

32 Écran tactile en pouces:

Mainly used for automation control systems that require advanced functions such as data analysis and processing, data visualization, and human-computer interaction.

Provide high-resolution touch screens that support complex data display and interactive operations.

PLC computer:

More suitable for automation tasks that require fast response and high-precision control, such as automation control on production lines, robot control, etc..

As its core, PLC is responsible for executing tasks such as logic control and signal processing, while touch screen provides human-computer interaction interface.

Coût

32 Écran tactile en pouces:

Due to the need for high computing and data processing capabilities, as well as large memory capacity and storage space, as well as high-definition touch screens, sturdy casings, and excellent heat dissipation design, the cost is relatively high.

PLC computer:

Its design is more streamlined, including only necessary input/output interfaces, contrôleurs, and communication interfaces, resulting in relatively lower costs.

Scalability and flexibility

32 Écran tactile en pouces:

The software and hardware have strong scalability and can adapt to various automation control application scenarios.

Provide advanced data analysis and processing capabilities, supporting multiple programming languages and development environments.

PLC computer:

The scalability of software and hardware is relatively poor, but it is stable, fiable, and has strong anti-interference ability, and can operate stably in complex industrial environments.

PLC programming is relatively simple, focusing more on real-time and reliability, and is suitable for specific industrial control needs.

En résumé, there are significant differences between industrial touch monitor and PLC computers in terms of structure and integration, functionality and usage, cost, as well as scalability and flexibility. The choice of device depends on the specific application scenario and requirements.