In today’s rapidly changing technological era, industrial production is moving towards intelligence and digitization at an unprecedented speed. U ovoj transformaciji, industrial touch displays are gradually reshaping the industrial standard of human-computer interaction with their unique technological advantages and application value, becoming an indispensable and important component of intelligent manufacturing.

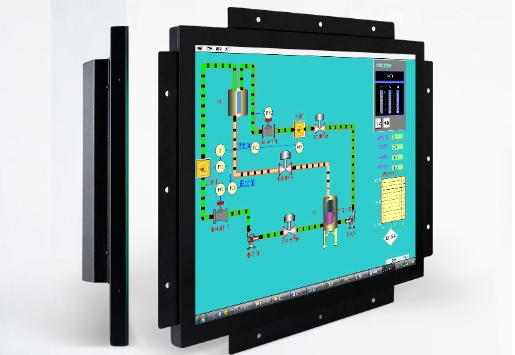

Tradicionalna sučelja za industrijsku kontrolu često se oslanjaju na složene gumbe, ručice, i indikatorska svjetla, which not only increases the difficulty of operation but also limits the improvement of production efficiency. Međutim, with the emergence of industrial touch displays, this situation has been completely changed. Industrial touch displays integrate touch screen technology, simplifying complex operating interfaces into intuitive and easy-to-use graphical interfaces. Workers only need to touch lightly to complete a series of operations such as device control, praćenje podataka, podešavanje parametara, itd. Ova metoda revolucionarne interakcije ne samo da smanjuje radni prag, ali također uvelike poboljšava radnu učinkovitost, čineći svaki korak rada proizvodnje preciznijim i učinkovitijim.

The author of the article noticed that industrial touch displays have particularly prominent advantages in industrial design. These displays are made of high-strength materials, which have characteristics such as dust-proof, waterproof, high temperature and low temperature resistance, i otpornost na vibraciju, and can operate stably under extreme conditions. Whether in high-temperature smelting workshops or humid chemical environments, industrial touch displays can ensure continuous operation of production lines and reduce downtime caused by equipment failures with excellent durability. This high stability and reliability make industrial touch displays an indispensable core device in industrial environments.

U Dodatku, industrial touch displays also have strong integration and scalability. Može prikupiti proizvodne podatke u stvarnom vremenu, Analizirajte i obrađujte putem oblaka ili lokalnih poslužitelja, i pružiti menadžerima sveobuhvatnu informacijsku podršku kao što je praćenje statusa proizvodnje, dijagnoza grešaka i upozorenje, prijedlozi za optimizaciju energetske učinkovitosti, itd. Ova sposobnost inteligentne integracije ne samo da povećava razinu rafiniranja u upravljanju proizvodnjom, ali također pruža solidan temelj za digitalnu transformaciju poduzeća. Istovremeno, industrial touch displays also support multiple input and output interfaces, such as USB, serial ports, network ports, itd., making it convenient to connect with various peripheral devices and achieve efficient data transmission and sharing.

It is worth mentioning that industrial touch displays have also shown great potential in customization. Potražnja za industrijskim dodirom prikazuje se u različitim industrijama i scenarijima primjene. For this reason, Mnogi proizvođači pružaju visoko prilagođene usluge, including screen size, rezolucija, operating system, interface configuration, and software customization, to ensure that each monitor can perfectly match the actual needs of customers. Ova fleksibilnost i prilagođavanje ne samo da poboljšavaju primjenjivost proizvoda, but also save unnecessary costs for the enterprise, achieving true “customization”.

S kontinuiranom integracijom vrhunskih tehnologija kao što je 5G, IoT, veliki podaci, i umjetna inteligencija, Industrijski dodirni zasloni razvijaju se prema inteligentnijem i međusobno povezanom smjeru. U budućnosti, we may see more advanced interaction methods such as gesture recognition and voice control being applied in industrial scenarios. U međuvremenu, kroz algoritme dubokog učenja, displays will be able to autonomously learn and optimize operational processes, Daljnje povećanje učinkovitosti i sigurnosti proizvodnje.

As the core device of human-computer interaction, industrial touch displays are leading the development of industrial production towards higher efficiency and intelligence. It not only improves the operational efficiency and product quality of the production line, but also reduces maintenance costs, injecting new vitality into the sustainable development of the enterprise. We have reason to believe that with the continuous advancement of technology and the continuous expansion of application scenarios, industrial touch displays will shine even brighter on the future path of intelligent manufacturing.