Entra in quasi tutti i McDonald's oggi, e sei accolto da un imponente, elegante lastra di vetro. Questi chioschi self-order hanno cambiato radicalmente il Quick Service Restaurant, o QSR, industria.

Per noi che lavoriamo nel settore manifatturiero, queste schermate rappresentano più di un menu; sono un sofisticato pezzo di ingegneria industriale. Ciò fa sorgere una domanda specifica: Chi produce effettivamente i chioschi self-order di McDonald’s?

Come produttore di monitor touchscreen, Ho analizzato i componenti all'interno di questi chioschi autoordinanti. È un ecosistema complesso di fornitori di hardware e architetti di software. Analizziamo la catena di fornitura, le specifiche tecniche, e l’economia dietro questa rivoluzione digitale.

I principali produttori di hardware dietro i chioschi

La ricerca di un adesivo generico con un marchio sul retro di un distributore McDonald’s di solito non rivela nulla. McDonald’s non acquista computer standardizzati; collaborano con integratori di soluzioni specializzati che comprendono le sfumature delle operazioni QSR.

Il produttore principale: Acrelec

Il nome dominante in questo spazio è Acrelec. Con sede in Francia ma operante a livello globale, Acrelec produce la stragrande maggioranza degli involucri dei chioschi e gestisce l'integrazione hardware per le sedi McDonald's, con eccesso 80,000 installazioni attraverso 80 Paesi.

Perché McDonald’s sceglie Acrelec? La scelta va oltre la semplice durata dell'hardware. Acrelec è stata fondata da ex veterani di McDonald’s, Jacques Mangeot e Jalel Souissi. Questo background dà loro una visione unica: comprendono il flusso operativo del ristorante dall'interno, consentendo loro di progettare soluzioni che si allineano perfettamente ai rigorosi standard di McDonald’s e ai flussi di lavoro in negozio.

Il loro vantaggio competitivo risiede in tre aree chiave:

- DNA operativo: A differenza dei produttori di custodie generalisti, Acrelec progetta chioschi che si integrano perfettamente con la produttività della cucina. Il loro hardware si concentra sull'efficienza ergonomica e sulla velocità del servizio, garantire che la tecnologia acceleri anziché ostacolare il processo di ordinazione.

- Scalabilità end-to-end: McDonald’s ha bisogno di un partner capace di un’implementazione globale standardizzata. Acreelec fornisce una soluzione coerente “Phygital” esperienza fondendo interazioni fisiche e digitali. Ciò garantisce la coerenza del marchio indipendentemente dal fatto che il chiosco venga distribuito a Parigi, New York, o Tokio.

- Gestione del ciclo di vita modulare: Le unità Acrelec presentano un'architettura altamente modulare. Ciò consente agli operatori di aggiornare componenti specifici, come terminali di pagamento o scanner, senza sostituire l'intero involucro. Questa modularità riduce drasticamente il costo totale di proprietà (TCO) durante la vita utile della macchina, che va dai 5 ai 7 anni.

Altri integratori hardware

Mentre Acreelec è il principale partner globale, McDonald’s utilizza una strategia multi-vendor per servire specifici mercati regionali:

- Computer piramidale: Dominante nel mercato europeo, nello specifico la Germania, La piramide è nota per la sua “Politocco” serie. Questa linea offre un'elevata personalizzazione e un'elegante integrazione estetica.

- Gruppo Coates: Uno dei principali attori nel merchandising digitale, particolarmente attiva nei mercati australiano e asiatico. Il loro obiettivo è integrare il chiosco nel più ampio ecosistema di segnaletica digitale del negozio.

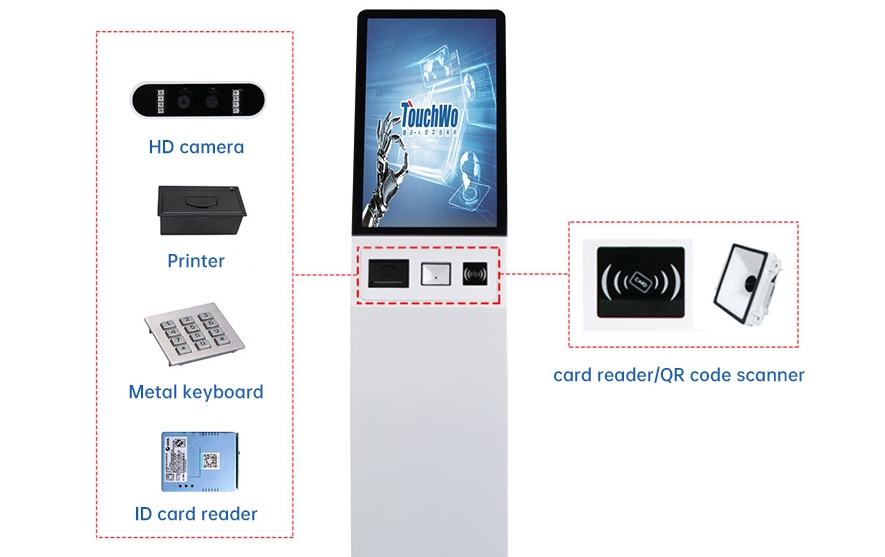

Indipendentemente dall'integratore specifico, il componente principale che definisce l'esperienza dell'utente è il capacitivo proiettato (PCAP) Touchscreen. Questa tecnologia di livello industriale non è più esclusiva dei franchising globali. A Touchwo, produciamo il nostro hardware rispettando esattamente gli stessi parametri di riferimento riscontrati in queste implementazioni di alto livello.

Ad esempio, Nostro 27-Chiosco touch con montaggio a parete da pollici, Modello GD27C, è progettato con Mohs Class 7 vetro antideflagrante. Ciò gli consente di resistere agli impatti fisici e ai rischi di graffio comuni negli ambienti QSR ad alto traffico. Inoltre, integriamo pannelli ad alta luminosità da 500–700 nit e periferiche essenziali, come stampanti e scanner, in una cornice ultrasottile da 13 mm. Questo design garantisce che le aziende possano accedere alla stessa durabilità operativa e modularità di un franchising McDonald’s, senza la necessità di un contratto di proprietà.

Gli sviluppatori di software e sistemi operativi

L'infrastruttura software che gestisce questi chioschi è spesso più complessa e costosa della macchina fisica stessa.

Il sistema operativo

Molti di questi chioschi funzionano su Windows 10 Impresa IoT. Questa scelta è pratica perché Windows offre un solido supporto dei driver per l'ampia varietà di periferiche collegate al sistema, come le stampanti per ricevute, scanner di codici a barre, e lettori di carte.

L'interfaccia e la logica

L'interfaccia utente e la gestione dei contenuti sono spesso gestiti da aziende come Stratacache o Evoke Creative. I loro sistemi consentono a McDonald’s di aggiornare i prezzi, voci di menu, e informazioni nutrizionali su migliaia di schermi istantaneamente.

Il vantaggio strategico: Rendimento dinamico

In 2019, McDonald’s ha acquisito una società tecnologica chiamata Dynamic Yield per circa $300 milioni. L’acquisizione è stata focalizzata interamente su logiche di personalizzazione del chiosco self-ordering di McDonald’s.

La tecnologia di Dynamic Yield utilizza i dati per regolare il menu in tempo reale in base a condizioni specifiche:

- Tempo atmosferico: Potrebbe suggerire un gelato nelle giornate calde o un caffè nelle giornate fredde.

- Carico della cucina: Può rimuovere temporaneamente articoli complessi se i dati della cucina mostrano un arretrato.

- Composizione dell'ordine: Può suggerire istantaneamente componenti aggiuntivi specifici in base a ciò che il cliente ha appena selezionato.

Questo automatizzato “vendita suggestiva” migliora l’efficienza e la coerenza, eliminando la variabile della performance umana nell’upselling.

Funzionalità di accessibilità e conformità ADA

Nel mercato statunitense, conformità con l’Americans with Disabilities Act (ADA) è un requisito fondamentale per la distribuzione dei chioschi. McDonald’s ha dovuto affrontare sfide legali in passato riguardanti l’accessibilità, portando a miglioramenti significativi nei loro progetti attuali.

La tastiera di navigazione

I modelli di chioschi più vecchi sono spesso dotati di un pad di navigazione quadrato con pulsanti fisici e un jack per le cuffie, tipicamente fornito da Storm Interface. Ciò consente agli utenti non vedenti di navigare nel menu utilizzando i tasti tattili mentre ascoltano le istruzioni audio.

Conformità basata su software

Le iterazioni moderne fanno molto affidamento sulle funzionalità del software per soddisfare le normative. Una caratteristica fondamentale è la modalità Reach, un pulsante che abbassa l'intera interfaccia interattiva fino al terzo inferiore dello schermo per renderla accessibile agli utenti su sedia a rotelle. Inoltre, i lettori di schermo integrati forniscono funzionalità di sintesi vocale per le opzioni di menu e i dati nutrizionali.

Approfondimento professionale: Progettare per l’accessibilità è una precisa sfida ingegneristica. Il controller touch deve essere abbastanza sensibile da registrare un tocco leggero, ma abbastanza sofisticato da respingere i falsi tocchi, come un utente che appoggia il palmo della mano sullo schermo per mantenere l'equilibrio. A Touchwo, vediamo anche una forte domanda di rivestimenti antiriflesso e anti-impronte per assistere gli utenti ipovedenti.

Quanto costa un chiosco McDonald's?

Parliamo di numeri. Un sistema completamente integrato, Si stima che il chiosco bifacciale utilizzato da una grande catena come McDonald's abbia un costo compreso tra $50,000 E $60,000.

Perché il costo è così alto?

Il prezzo non include solo i materiali fisici:

- Marchio Premium: L'approvvigionamento di hardware da fornitori globali di livello 1 comporta un aumento significativo dei prezzi.

- Commissioni di licenza: I costi ricorrenti per il software proprietario e l'integrazione POS si sommano rapidamente.

- Contratti di servizio: I costosi contratti di manutenzione in loco sono standard.

- Eccessiva ingegneria: Queste unità sono costruite secondo specifiche estreme che possono superare le reali esigenze di un ambiente di vendita al dettaglio standard.

Per una multinazionale, questo costo viene assorbito in milioni di transazioni. Tuttavia, per rivenditori indipendenti o piccoli franchising, l'alto prezzo del chiosco per ordini self-service di $60,000 per una singola unità è spesso un problema.

Perché i chioschi aumentano la dimensione media degli assegni

Investire molto negli ordini digitali ripaga perché i calcoli creano un argomento convincente. I dati lo dimostrano costantemente chioschi autoordinanti aumentare la dimensione media dell'assegno di 20% A 30%.

Il meccanismo dell’upselling digitale

Ci sono ragioni pratiche per questo aumento delle entrate:

- Pressione ridotta: I clienti spesso si sentono più a loro agio nell'ordinare pasti più grandi o articoli extra senza il giudizio percepito del cassiere.

- Impatto visivo: Immagini di alta qualità di cibi e bevande stimolano gli acquisti d’impulso in modo più efficace rispetto al testo su una bacheca del menu.

- Coerenza: Il chiosco non dimentica mai di fare upselling. Chiede ad ogni cliente di aggiungere una bevanda o un contorno, garantendo il massimo ricavo per transazione.

Questo ritorno sull'investimento (ROI) significa che la macchina alla fine si ripaga da sola, sebbene il periodo di rimborso su a $60,000 l'unità è significativa.

La buona notizia: Puoi raggiungere questo obiettivo 30% aumento delle entrate senza il $60,000 cartellino del prezzo. Hai semplicemente bisogno di un'interfaccia touch affidabile.

Costruire una soluzione chiosco personalizzata con Touchwo

La tecnologia all’interno di un chiosco McDonald’s è modulare. Ciò significa che puoi replicare la funzionalità con un budget più ridotto acquistando direttamente l'hardware.

Fondamentalmente, un chiosco self-order è un computer abbinato a un display di livello professionale. Lavorando direttamente con un produttore, bypassi il “imposta sul marchio” e ottenere il controllo sulle specifiche.

Touchwo opera come un'impresa high-tech con la nostra R&Centri D e impianti di produzione. Specializzato in soluzioni tattili industriali da allora 2009, controlliamo l'intero processo dalla progettazione all'assemblaggio.

IL “Diretto in fabbrica” Vantaggio

Le aziende intelligenti spesso adottano il “Cornice aperta” approccio per evitare markup proprietari. Acquistate i componenti industriali direttamente dalla fabbrica e li integrate nei vostri mobili o stand.

Come ISO 9001 produttore certificato, Touchwo fornisce la base hardware fondamentale per il tuo chiosco personalizzato:

- Professionista R&D e personalizzazione (ODM/OEM): Ogni progetto ha vincoli unici. Se hai bisogno di uno schermo ad alta luminosità per una finestra soleggiata, una struttura di montaggio specifica, o una porta di interfaccia personalizzata, il nostro R&La squadra D sostiene in profondità personalizzazione. Offriamo produttore di design originale (ODM) e produttore di apparecchiature originali (OEM) servizi per adattare l'hardware esattamente alle specifiche del tuo progetto.

- Affidabilità industriale per 24/7 Operazione: I nostri PC e monitor touch all-in-one sono realizzati con schede driver di livello industriale e strutture di dissipazione del calore in lega di alluminio. Ciò garantisce che possano funzionare continuamente, 7 giorni alla settimana, 24 ore al giorno, senza surriscaldamento: un requisito fondamentale per i settori QSR e vendita al dettaglio.

- Integrazione versatile del prodotto: Offriamo completo, informatica integrata soluzioni. Puoi scegliere dalla nostra gamma di PC All-in-One con touch capacitivo con Windows o Android, oppure opta per i nostri monitor touch Open Frame se disponi già di un lettore multimediale separato. I nostri prodotti supportano un'ampia gamma di dimensioni, dalle unità compatte da 10,1 pollici agli ampi display da 55 pollici adatti ai chioschi di grande formato.

- Standard di certificazione globali: Quando si costruisce un chiosco per uso pubblico, la sicurezza e la conformità non sono negoziabili. Touchwo i prodotti sono dotati delle principali certificazioni internazionali, compreso CE, FCC, RoHS, e HDMI. Ciò ti dà la certezza che l'hardware principale soddisfa rigorosi standard globali di sicurezza e ambientali.

Pensieri finali

McDonald’s ha educato il mercato all’utilizzo dei chioschi self-order. Ora, questa tecnologia è accessibile a tutti.

Non è necessario essere un franchising globale per automatizzare il tuo servizio; hai solo bisogno del giusto partner di produzione. Che tu sia un integratore di sistemi alla ricerca di una fornitura costante di monitor open-frame o un imprenditore che crea una soluzione personalizzata, Touchwo fornisce l'hardware di livello professionale per realizzarlo.

Sei pronto per definire una soluzione kiosk personalizzata? Contattaci oggi per discutere i requisiti del tuo progetto.