In the wave of Exibição do toque industrial 4.0, A inovação tecnológica está reformulando a face da produção industrial a uma velocidade sem precedentes. Nesta transformação, Displays de toque industrial, Como um dispositivo chave para a interação humano-computador, estão gradualmente emergindo como uma ponte que conecta o mundo físico e o mundo digital. Hoje, Vamos nos aprofundar no papel central desempenhado por exibições industriais de toque na indústria 4.0 era, com rigor e objetividade consistentes da BBC.

Indústria 4.0: Uma nova era de fabricação inteligente

Indústria 4.0, desde a sua criação, liderou a transformação e a atualização da indústria de manufatura global com sua previsão e inovação. Ele enfatiza a integração e aplicação de tecnologias avançadas, como a Internet das Coisas, big data, e computação em nuvem para obter inteligência, em rede, e processos de produção automatizados. Nesse contexto, As exibições de toque industrial tornaram-se uma parte indispensável de sistemas de fabricação inteligentes devido à sua interação humano-computador intuitiva e eficiente.

Interação intuitiva, operação simplificada

Comparado com os painéis de controle industrial tradicionais, Exibições de toque industrial simplificam bastante o processo de operação com sua interface intuitiva e funções de exibição de informações ricas. Os trabalhadores podem concluir rapidamente a inicialização do equipamento, Configuração de parâmetros, diagnóstico de falhas e outras operações com apenas um toque suave, Melhorando bastante a eficiência do trabalho. Ao mesmo tempo, As exibições de toque industrial também suportam a troca de múltiplas idiomas, Atendendo às necessidades de uso dos trabalhadores em diferentes países e regiões, promovendo ainda mais o processo global de fabricação inteligente.

Monitoramento inteligente, resposta em tempo real

Na era da indústria 4.0, A coleta e análise de dados em tempo real são cruciais para otimizar os processos de produção. Displays de toque industrial integram sensores avançados e tecnologias de processamento de dados, permitindo o monitoramento em tempo real do status operacional das linhas de produção e exibir dados em formas intuitivas, como gráficos e curvas. Isso não apenas ajuda os trabalhadores a descobrir e resolver possíveis problemas em tempo hábil, mas também fornece suporte de dados valiosos para as empresas otimizam os processos de produção, melhorar a qualidade do produto, e reduzir os custos operacionais.

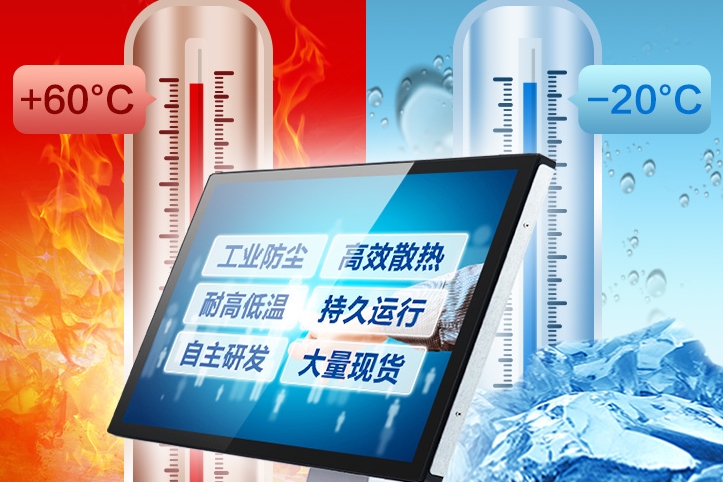

Design durável, Adaptável a ambientes severos

Ambientes industriais geralmente são complexos e em constante mudança, colocando demandas extremamente altas na durabilidade e estabilidade do equipamento. Displays de toque industrial use special materials and reinforced designs to resist the effects of harsh conditions such as dust, vapor de água, e vibração, Garantir a operação normal, mesmo em ambientes extremos. Este design de alta durabilidade não apenas estende a vida útil do equipamento, mas também garante a continuidade e a estabilidade da linha de produção.

Serviços personalizados para atender às diversas necessidades

A demanda por displays de toque industrial varia em diferentes indústrias e cenários de aplicação. Para atender a esta demanda, Muitos fabricantes oferecem soluções personalizadas. Do tamanho da tela, resolução, Modo de toque para design de interface de software, e até a integração de funções especiais, Eles podem ser profundamente personalizados de acordo com as necessidades reais dos clientes. Esse alto grau de flexibilidade e serviço personalizado não apenas atende às necessidades diversificadas do mercado, mas também promove a inovação contínua e o desenvolvimento da tecnologia de exibição de toque industrial.

Perspectivas futuras: Mais inteligente e eficiente

Com o desenvolvimento contínuo de tecnologias como inteligência artificial, A Internet das Coisas, e 5g, As exibições de toque industrial se tornarão mais inteligentes e eficientes no futuro. Eles poderão apoiar melhor funções avançadas, como manutenção preditiva e produção adaptativa, fornecendo suporte mais abrangente e aprofundado para a fabricação inteligente. Enquanto isso, Combinando com tecnologias como dispositivos vestíveis inteligentes e realidade virtual, As exibições de toque industrial também fornecerão aos trabalhadores uma experiência de trabalho mais conveniente e segura.

epílogo

Como o principal dispositivo de interação humana-máquina na indústria 4.0 era, As exibições de toque industrial estão impulsionando o rápido desenvolvimento da fabricação inteligente com suas vantagens únicas. Eles não apenas simplificam o processo de operação e melhoram a eficiência da produção, mas também atenda às diversas necessidades do mercado por meio de monitoramento inteligente e serviços personalizados. Olhando para frente, Temos motivos para acreditar que, com o avanço da tecnologia avançada, As exibições de toque industrial desempenharão um papel mais importante no campo da fabricação inteligente, contribuindo para a construção de um mais eficiente, inteligente, e sistema industrial sustentável.