Food Processing Plant Requirements

Must withstand daily high-pressure water and chemical cleaning

Dust Isolation Requirement:Complete isolation from flour and powder particles

Enclosed Thermal Management:Effective heat dissipation in protective enclosure

Corrosion Resistance:Resistance to acidic and alkaline cleaning agents

Hygienic Design

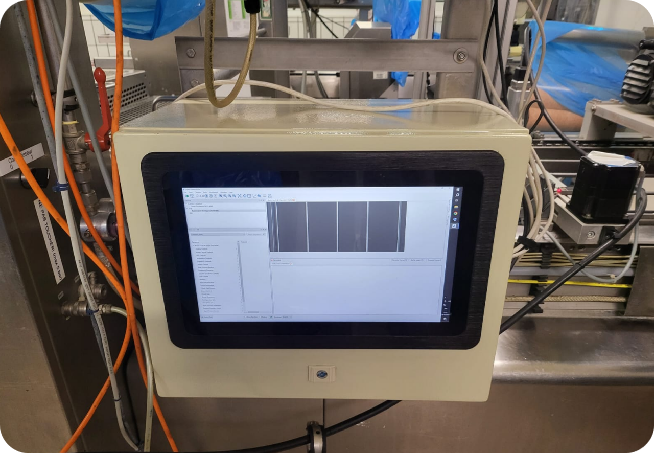

TouchWo Solution

DM101 Embedded in Custom 304 Stainless Steel Enclosure

Ensures entire system meets IP69K dust/water protection rating.

Thermal Management System

Industrial fanless motherboard with built-in thermal silicone paste for heat conduction, coupled with raised heat dissipation fins on rear housing.

High-Sensitivity Capacitive Touchscreen

Guarantees normal touch operation with water exposure or gloves.