Capacitive touch screens are widely used in smartphones, tablets, kiosks, industrial equipment, and interactive displays. These screens are known for their responsiveness and multi-touch capability. However, over time or due to environmental factors, they may become less accurate, requiring a process called capacitive touch screen calibration.

In this guide, we’ll walk you through everything you need to know—from understanding what calibration is to how and when to perform it, troubleshooting tips, and what to do if calibration doesn’t work. Whether you’re an end-user, technician, or business buyer, this guide is designed to help you make informed decisions.

What Is Capacitive Touch Screen Calibration?

Capacitive touch screen calibration refers to the process of adjusting the touch sensitivity and accuracy of a screen to ensure it correctly registers the user’s input. Unlike resistive screens, which rely on pressure, capacitive screens detect touch through the electrical properties of the human body.

Over time, or due to hardware/software changes, the screen may begin to misinterpret touch points—such as responding inaccurately, slowly, or inconsistently. Calibration helps restore the proper alignment between your physical touch and the display’s digital response.

When Should You Calibrate a Capacitive Touch Screen?

Not all capacitive touch screens require frequent calibration, but there are specific scenarios where it’s recommended:

- Inaccurate touch response: Touch points appear offset from your actual finger position.

- Delayed responsiveness: The screen lags or is slow to register touch.

- Screen drift: The touch point drifts away over time, making the screen unreliable.

- Post system update or hardware change: Firmware updates or replacement of components may affect touch sensitivity.

- Extreme environmental changes: High humidity, static interference, or temperature shifts can affect performance.

If you experience any of these issues, calibration is a good first step before replacing the screen.

Tools and Software Required for Capacitive Touch Screen Calibration

Calibration processes can vary depending on the operating system, hardware configuration, and manufacturer. Here are some common tools and utilities:

- Windows OS: Built-in calibration tool (Control Panel > Tablet PC Settings > Calibrate).

- Android devices: Some manufacturers include touchscreen calibration tools in Developer Settings.

- Linux systems: Use xinput_calibrator or touch-specific configuration files.

- Embedded systems or kiosks: OEM-provided drivers or software utilities.

Some industrial or custom-built monitors require proprietary software from the touch screen monitor manufacturer like Touchwo, which may include advanced diagnostics and calibration features.

How to Calibrate a Capacitive Touch Screen: Step-by-Step Instructions

Calibrating your capacitive touch screen helps restore accurate and responsive touch input. Follow the steps below to perform the calibration correctly.

Step 1: Clean the Touch Screen

Gently clean the screen with a lint-free microfiber cloth to remove dust, fingerprints, or moisture that may interfere with touch detection.

Step 2: Open the Calibration Tool

Access the calibration utility on your device:

- Windows: Control Panel > Hardware and Sound > Tablet PC Settings > Calibrate

- Linux: Use xinput_calibrator or other platform-specific tools

- Embedded/industrial systems: Launch your device’s OEM calibration software

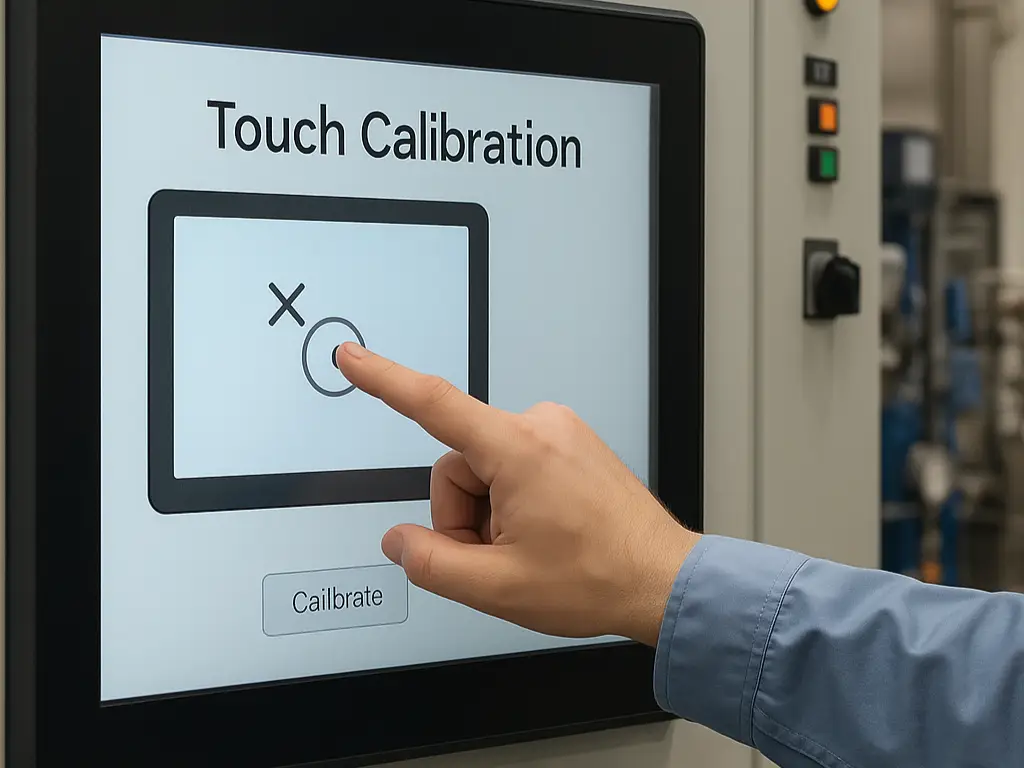

Step 3: Follow the On-Screen Calibration Process

Touch each target point on the screen (usually corners and center) exactly as shown. Accurate touches are essential for proper alignment and sensitivity.

Step 4: Save Settings and Test the Screen

After completing the calibration, confirm or save the results. Test by opening apps, tapping buttons, and dragging objects to ensure proper response.

Step 5: Reboot If Required

Some systems need a reboot to apply calibration changes. If issues persist, repeat the process or check for software updates or hardware issues.

Note: For industrial systems, always follow the manufacturer’s specific calibration method to avoid compatibility issues.

Capacitive vs Resistive Touch Screen Calibration: Key Differences

| Feature | Capacitive Touch Screen | Resistive Touch Screen |

| Touch Detection | Uses electrical conductivity (finger) | Uses pressure (stylus/finger) |

| Calibration Frequency | Rare, only when issues occur | More frequent due to physical wear |

| Accuracy Adjustment | Software-based, more complex | Easier with analog circuits |

| Multi-touch Support | Yes | Limited or none |

| Environmental Sensitivity | More sensitive to EMI and humidity | More tolerant |

Capacitive touch screen monitors offer a more intuitive user experience, but require precise tuning, especially in industrial and outdoor environments.

How to Maintain Accuracy After Calibration

To extend the performance and lifespan of your calibrated capacitive touch screen:

- Keep the screen clean: Oil and dust buildup can interfere with conductivity.

- Avoid strong EMI sources: Electromagnetic interference from nearby equipment can disrupt the capacitive field.

- Use a compatible power supply: Voltage instability can affect touch controller behavior.

- Update firmware: Some calibration bugs are resolved through firmware updates.

- Use proper touch gestures: Avoid pressing too hard or using incompatible styluses.

Periodic checks and preventive maintenance can help avoid recurring calibration issues.

Troubleshooting Calibration Problems

Sometimes, even after following all calibration steps, issues may persist. Here’s what to try next:

- Reboot the system: Sometimes touch drivers don’t reset until a full restart.

- Check driver compatibility: Ensure you’re using the correct version for your OS.

- Disconnect peripherals: Other USB or serial devices may interfere with touch input.

- Reinstall touch controller drivers: Corrupted drivers may cause erratic behavior.

- Check hardware condition: Cracks, delamination, or moisture inside the panel may permanently affect touch function.

If you’ve ruled out software issues, hardware replacement may be the next logical step.

What to Do If Capacitive Touch Screen Calibration Doesn’t Work

If calibration doesn’t resolve the issue, it’s possible your touch screen is:

- Damaged or worn out: Overuse, aging, or physical damage can affect sensitivity.

- Affected by environmental factors: Industrial or outdoor conditions may exceed your screen’s tolerance.

- Built with outdated components: Older touch controllers may not support newer OS calibrations.

In such cases, replacing the screen—or upgrading to an industrial-grade unit—is often more cost-effective than ongoing repairs. Be sure to choose a reliable touch screen monitor manufacturer that provides support for your specific application, whether consumer, commercial, or industrial.

Work with a Touch Screen Monitor Manufacturer You Can Trust

While calibration can solve many touch-related issues, it’s only one piece of the puzzle. As a professional touch screen monitor manufacturer, we provide not only high-quality hardware but also full lifecycle support—including calibration tools, driver assistance, customization, and after-sales service.

Here’s what sets us apart:

✅ OEM/ODM custom manufacturing to fit your unique use case

✅ High durability with options for waterproof, anti-glare, and glove-friendly touch screens

✅ Support for industrial environments with EMI shielding and extended temperature ranges

✅ Complete technical documentation and driver integration support

✅ Fast lead times and global shipping

Whether you’re building self-service kiosks, industrial touch screen monitors or industrial PCAP touch screen PC, we help ensure that your touch screen always—from the first touch to long-term operation.

Need a new solution or expert advice? Contact our team today to discuss your project or request a quote.