In today’s rapidly changing technological era, industrial production is moving towards intelligence and digitization at an unprecedented speed. In this transformation, industrial touchscreen display are gradually reshaping the industrial standard of human-computer interaction with their unique technological advantages and application value, becoming an indispensable and important component of intelligent manufacturing.

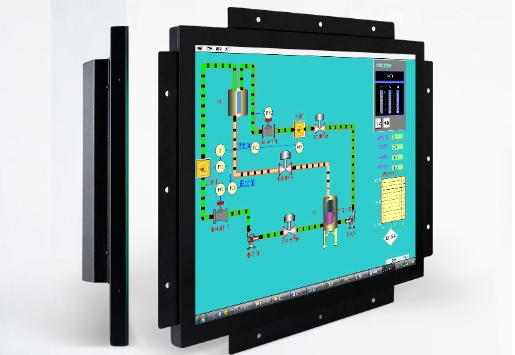

Traditional industrial control interfaces often rely on complex buttons, knobs, and indicator lights, which not only increases the difficulty of operation but also limits the improvement of production efficiency. However, with the emergence of industrial touch displays, this situation has been completely changed. Industrial touch displays integrate touch screen technology, simplifying complex operating interfaces into intuitive and easy-to-use graphical interfaces. Workers only need to touch lightly to complete a series of operations such as device control, data monitoring, parameter adjustment, etc. This revolutionary interaction method not only lowers the operating threshold, but also greatly improves work efficiency, making every step of the production line operation more precise and efficient.

The author of the article noticed that industrial touchscreen display have particularly prominent advantages in industrial design. These displays are made of high-strength materials, which have characteristics such as dust-proof, waterproof, high temperature and low temperature resistance, and vibration resistance, and can operate stably under extreme conditions. Whether in high-temperature smelting workshops or humid chemical environments, industrial touchscreen display can ensure continuous operation of production lines and reduce downtime caused by equipment failures with excellent durability. This high stability and reliability make industrial touch displays an indispensable core device in industrial environments.

In addition, industrial touch displays also have strong integration and scalability. It can collect production data in real-time, analyze and process it through cloud or local servers, and provide managers with comprehensive information support such as production status monitoring, fault diagnosis and warning, energy efficiency optimization suggestions, etc. This intelligent integration capability not only enhances the level of refinement in production management, but also provides a solid foundation for the digital transformation of enterprises. At the same time, industrial touch displays also support multiple input and output interfaces, such as USB, serial ports, network ports, etc., making it convenient to connect with various peripheral devices and achieve efficient data transmission and sharing.

It is worth mentioning that industrial touchscreen display have also shown great potential in customization. The demand for industrial touch displays varies across different industries and application scenarios. For this reason, many manufacturers provide highly customized services, including screen size, resolution, operating system, interface configuration, and software customization, to ensure that each monitor can perfectly match the actual needs of customers. This flexibility and customization not only enhance the applicability of the product, but also save unnecessary costs for the enterprise, achieving true “customization”.

With the continuous integration of cutting-edge technologies such as 5G, IoT, big data, and artificial intelligence, industrial touch displays are developing towards a more intelligent and interconnected direction. In the future, we may see more advanced interaction methods such as gesture recognition and voice control being applied in industrial scenarios. Meanwhile, through deep learning algorithms, displays will be able to autonomously learn and optimize operational processes, further enhancing production efficiency and safety.

As the core device of human-computer interaction, industrial touch displays are leading the development of industrial production towards higher efficiency and intelligence. It not only improves the operational efficiency and product quality of the production line, but also reduces maintenance costs, injecting new vitality into the sustainable development of the enterprise. We have reason to believe that with the continuous advancement of technology and the continuous expansion of application scenarios, industrial touch displays will shine even brighter on the future path of intelligent manufacturing.